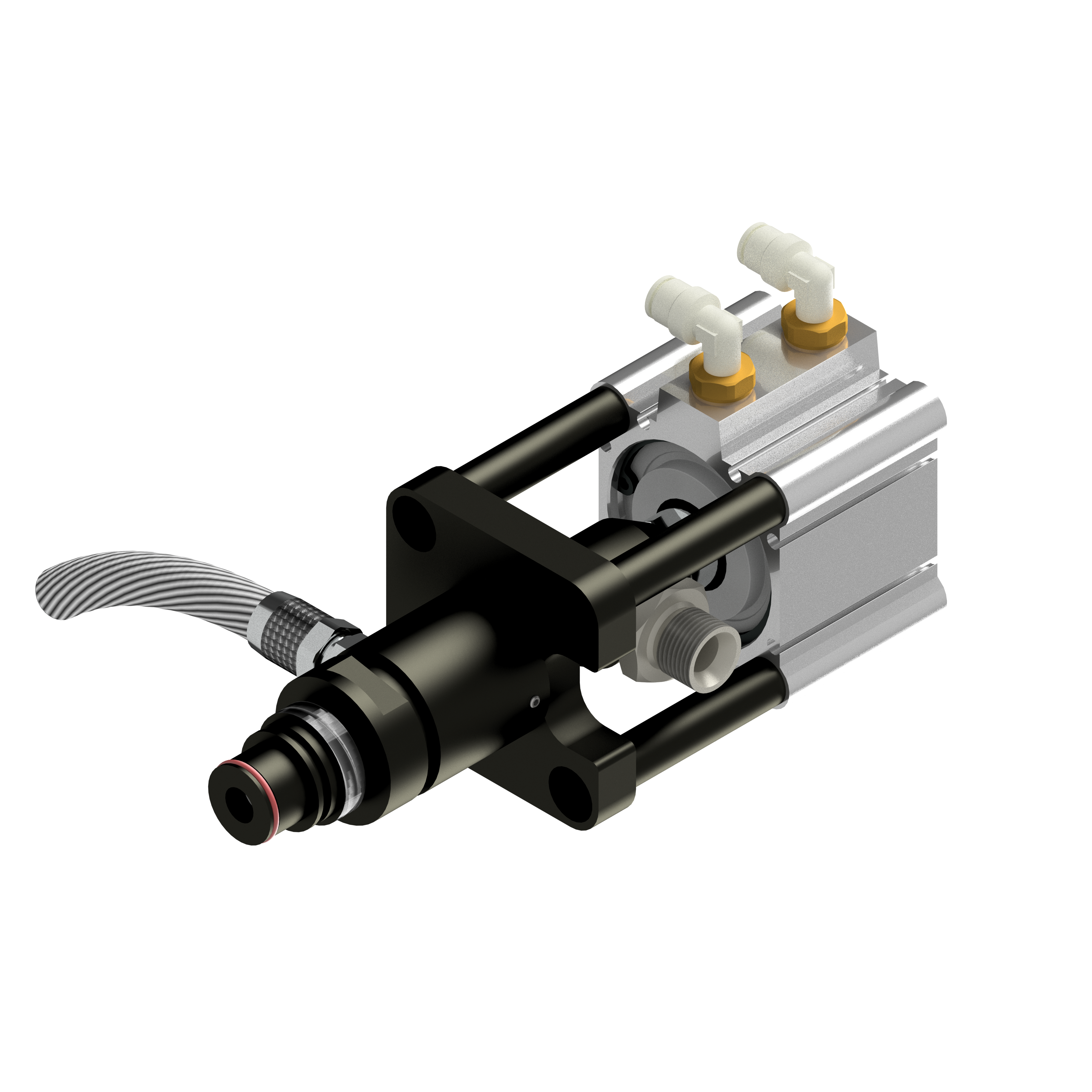

ABOUT CIJECT 0

CIJECT 0 is an entry level two component resin mixing and injection machine that is very simple to operate, very easy to maintain and incredibly reliable.

With a maximum output of up to 10Kg/min it is suitable for RTM, VRTM and small infusions.

- Share Options

Key Features & Benefits

- A simple and effective manual control system – very easy to operate.

- Onboard Flush system with gel alarm – quick and efficient cleaning.

- Purpose designed piston pumps – very reliable & easy to maintain.

Applications

- RTM of boat hatches

- VRTM of van panels & roofs

- Small infusions

Datasheet

Where To Buy

Looking to purchase this product? Visit our Worldwide Partners page to find a distributor near you. Our global network of trusted partners is ready to assist with your Composite Integration machinery needs. Click the button below to view the map and get in touch with your local distributor.

You May Also Need

Injection Valve

Part Number:

XE-0015

Vacuum Catch-Pot – c/w Lid

Part Number:

XE-0211

Inline Resin Trap

Part Number:

XE-0213