ABOUT CIJECT 2

CIJECT 2 is a high-performance two component resin mixing and injection machine designed for applications requiring levels of control and verification. With multi-stage programmable recipes, A & B component flow meters and In-Mould Pressure Sensors (IMPS) the CIJECT 2 will manage the injection process to ensure that the same injection parameters are repeated time after time.

- Share Options

Key Features & Benefits

- Advanced powerful PLC that enables unrivalled levels of control.

- Wi-Fi functionality enables remote status updates and data logging, increasing the efficiency of operatives.

- RFID scanner to enable auto ID of injection parameters, minimising the reliance on operator input.

- Option for integrated material conditioning tanks, with a single point of control for complete process management.

Applications

- RTM of multiple mould tools.

- RTM of complex geometries.

- Infusion up to 1200Kg

- Programmable multistage infusion process

Datasheet

Where To Buy

Looking to purchase this product? Visit our Worldwide Partners page to find a distributor near you. Our global network of trusted partners is ready to assist with your Composite Integration machinery needs. Click the button below to view the map and get in touch with your local distributor.

You May Also Need

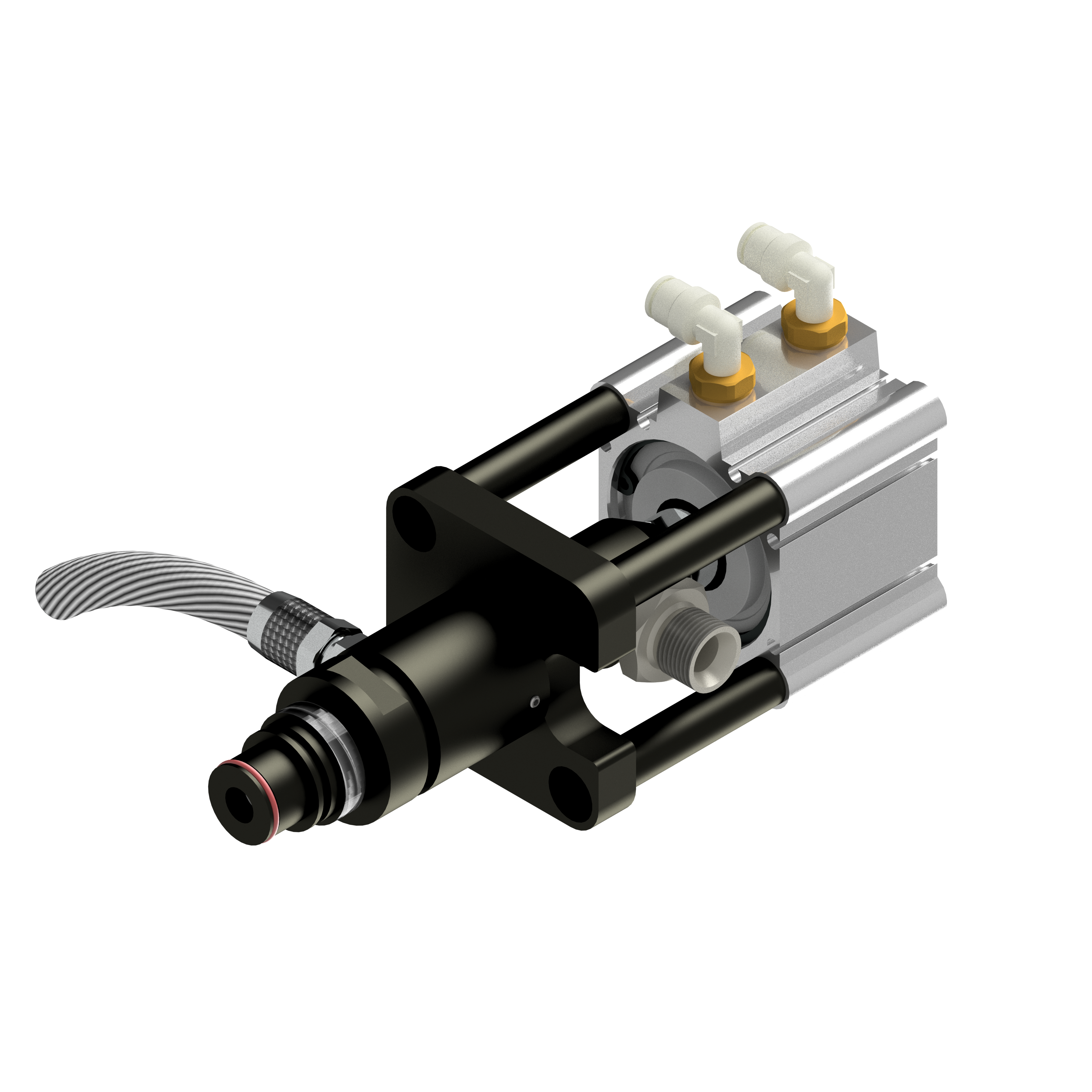

Injection Valve

Part Number:

XE-0015

Vacuum Catch-Pot – c/w Lid

Part Number:

XE-0211

Inline Resin Trap

Part Number:

XE-0213