(for two Component Resins)

www.composite-integration.co.uk

info@composite-integration.co.uk

Tel +44 (0)1752 849998

Fax +44 (0)1752 846414

Composite Integration Ltd

1F Long Acre, Saltash, PL12 6LZ

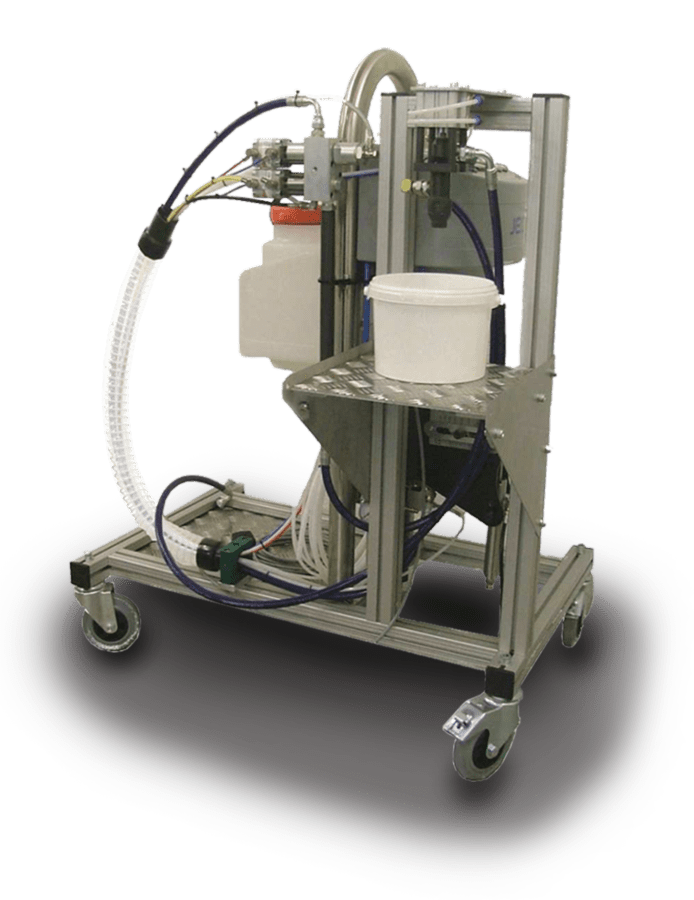

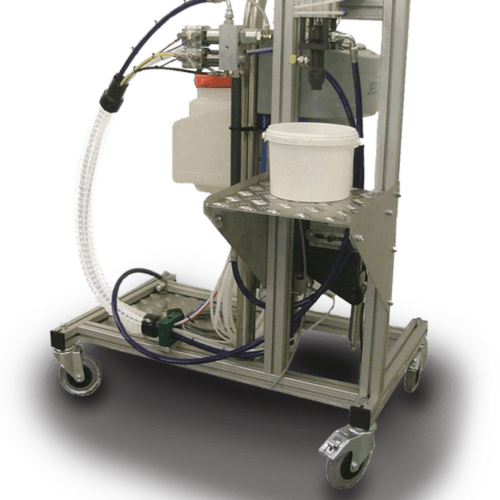

Ciject® Metering/Dispensing Machine (for two Component Resins)

Metering and dispensing machine available for use with Polyester/Vinylester or Epoxy resin and hardener systems.

Features include:

- Robust production-proven construction

- Simple and reliable operator control

- Purpose designed resin and 316 Stainless Steel catalyst/hardener pumps for high reliability and simple maintenance

- Adjustable dispense Ratio from 0.5% to 4% resin/catalyst (polyester/vinylester version or 100:12.5 to 100:50 resin/hardener (epoxy version) or 1% to 8% (phenolic version)

- Variable dispensing speed

- Variable preset dispense quantity (if ‘Plus’ option is specified)

- Resin and hardener recirculation system

Note: Base machine does not include mixing-head. The two materials are fed to separate dispense nozzles via auto recirculation valves (mounted above the dispensing platform)

Material can be recirculated up to these valves, and then back to the material containers to allow efficient priming without material wastage.

Dispensing Machine Options

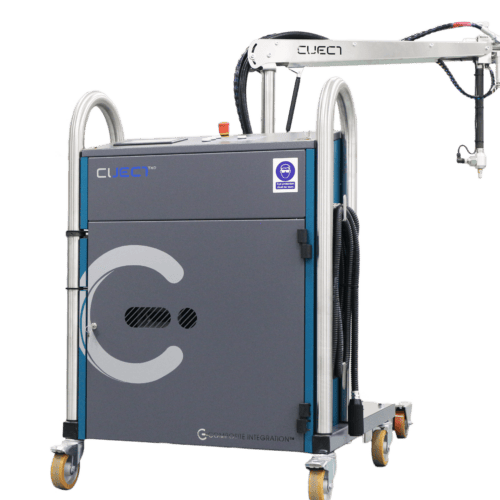

Mixing Head

Fixed Dispensing valve

‘Plus’ Option

Option to enable additional control functions:

High Flow Head Option

High Flow Hose Option

How to specify / order

| Machine Item/Option | Notes | Part/Option Number |

|---|---|---|

| Ciject Dispensing Machine | Standard option is non-mixing | XE-0001 |

| Polyester Version | 0.5% - 4% ratio range | 01 |

| Epoxy Version 2:1 | 100:12.5 - 100:50 ratio range | 02 |

| Epoxy Version 1:1 | 100:25 - 100:100 ratio range | 03 |

| Phenolic Version | 1% - 8% ratio range | 04 |

| Options | XE-0001-OPT | |

| Mixing | Includes flushing systems (suitable for all versions) | 05 |

| Fixed Dispensing Valve | 06 |

|

| ‘Plus’ Option | 07 |

|

| High-Flow Mix-Head | 08 |

|

| High-Flow Hose Kit | 09 |

|

| Spares Kits | XE-0001-SK-OPT |

|

| Polyester Option | 0.5% - 4% ratio range | 01 |

| Epoxy Option | 100:12.5 - 100:50 ratio range | 02 |

| Epoxy Option | 100:25– 100:100 ratio range | 03 |

| Phenolic Option | 1% - 8% ratio range | 04 |

| Mix-Head Option | 05 | |

| Dispensing Valve Option | 06 |

|

| High-Flow Mix-Head Option | 07 |

|

| High-Flow Hose Option | 08 |

|

| Conversion Kits | Kits available to convert machines to process alternative resin types – specification and prices on request | XE-0001-CK |

| Polyester to Epoxy 100:50 | 01 |

|

| Epoxy 100:50 to Polyester | 02 |

|

| Polyester to Phenolic | 03 |

|

| Phenolic to Polyester | 04 |

|

| Epoxy 100:100 to Polyester | 05 |

|

| Epoxy 100:50 to Epoxy 100:100 | 06 |

|

| Epoxy 100:100 to 100:50 | 07 |

|

| Servicing | XE-0001-SERVICE |

To specify a machine configuration use the machine part number followed by the required option numbers separated by a hyphen.

e.g. XE-0001-01-07 specifies a Ciject Zero dispensing machine Polyester version with a ‘Plus’ option.