www.composite-integration.co.uk

info@composite-integration.co.uk

Tel +44 (0)1752 849998

Fax +44 (0)1752 846414

Composite Integration Ltd

1F Long Acre, Saltash, PL12 6LZ

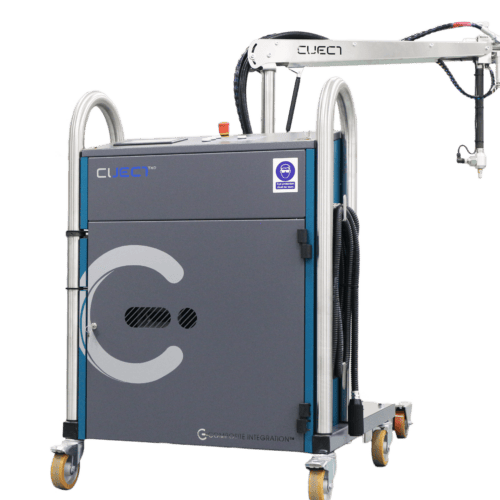

Infusion Machine

The Ciject® Five has been developed as an extension of the existing Ciject range of meter-mixing injection/infusion machines.Designed specifically for large scale infusion processing, the Ciject Five uses precision gear pumps to achieve output rates.

The Ciject® Five is designed to achieve the following:

- To replace manual resin mixing and handling in the infusion process.

- To connect directly and cleanly to bulk material storage tanks.

- To automatically pump and mix resin/hardener and maintain ratio accuracy over the entire output range.

- To dispense the mixed resin directly into the infusion process.

- To automatically control the rate of injection based on pressure feedback from the mould.

- To enable the operator to have full control of the process with relevant checks, interlocks/alarms and feedback before and during the process.

- To be easily, safely and efficiently flushed/cleaned after the process.

- To enable real-time process data to be recorded.

Significant Technical Benefits:

- The ability to accurately control infusion pressure at the bag inlet point to a resolution of 100mbar whilst continually infusing at varying rate. Infusion can be controlled by either pressure (with a maximum flow rate limit), or, flow rate (with a maximum pressure limit). This fine control allows continuous infusion (not stop/start) without ever causing over-pressurisation (bag blistering).

- Ratio control with continual PID control between A & B components and verification using a predicted/measured flow method. This methodology provides a high confidence level in both the operation of the pumps, flow meters and the final measured ratio.

- The ability to control infusion pressure between 100mbar abs and 1000mbar abs enables the control of the bag consolidation pressure. Typical infusion pressure is 700mbar abs which leaves a positive pressure on the bag of 300mbar or 3 tons/meter sq. The ability to restrain flow in this manner enables user control of final volume fraction. Confirmation of these unique capabilities can be evidenced from existing infusions of up to 8 tons resin quantity.

- The equipment can monitor up to 4 in-bag sensor inputs per mixing unit and any monitored sensor may be used at any point during the infusion for process control. This gives highly accurate control and great flexibility of infusion strategy. Additional IMPS inputs available (see options)

- The equipment contains an onboard flushing system. No resin purging is required to clean the mixing unit. Solvent usage is minimal (up to 1 litre maximum). Time to clean is approx 3-4 minutes.

- A range of ‘pre-infusion’ checks can be incorporated into the software to assist with the preparation for infusion. These can include:

- Incoming material temperature verification

- Recirculation checks to validate flow rates of material (pseudo viscosity check)

- Dispense check to validate material flow rate

- Vacuum drop tests using IMPS sensors already connected in bag

- Operator checks

- IBC material levels

General Specification

General Specification:

| Machine Item | Details | Notes |

|---|---|---|

| Total machine output (based on typical specification) | 2 to 25 litres/minute | Depending on mix ratio and length and diameter of down-stream pipe-work (other pump sizes can be specified) |

| Pumping system resin | 2 to 25 litres/min | Gear type pump (cast iron/steel) with vector drive |

| Pumping system Catalyst/hardener | Flow rates to suit material set-up | Gear type, magnetically coupled pump (stainless steel) with servo/vector drive |

| Flow measurement resin | To suit range | Gear type flow meter. With alarm at +/- 2% off set ratio |

| Flow measurement catalyst-hardener | To suit range | Gear or piston type flow meter. With alarm at +/- 2% off set ratio |

| Pressure control | Internal monitoring and IMPS | Pressures monitored internally and at the bag inlets. Output controlled from IMPS sensor(s) in mould. All sensors can be monitored simultaneously. |

| Mix Head | High-flow type | Includes actuated recirculation valves |

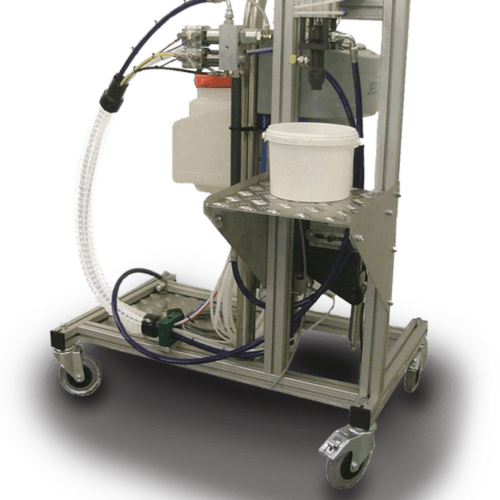

| Flushing system | Air/solvent/air | Non-pressurised tank, manual and automatic operation |

| Solvent level sensor | Capacitive | Non-intrusive with adjustable set points |

| Control system | Omron PLC | Modular high performance PLC |

| HMI | Colour touch screen | Omron 10” Colour HMI |

| Programmable settings | Via HMI | Mix ratio, quantity, pressure, IMPS selection, recipe, etc |

| Alarms/interlocks | Mix ratio, over pressure, solvent level, pre-infusion recirc/viscosity check. Visual and audible alarms with beacon |

|

| IMPS | -1 to +3 bar | Standard specification includes four IMPS inputs (switchable) Expandable (see options) |

| Mobility | 4 wheels | Heavy duty Lockable |

| Material Connections | IBC | To match IBCs, includes isolation valves |

| Maintenance functions | Material sampling | Test facility to dispense output sample before each infusion |

| Data recording | ||

| Compressed air requirements | 8 bar @ max 10cfm | |

| Power supply requirements | 3 x 415V 50Hz | Approx 16 A |

Ciject® Five Machine Options

On-board vacuum system

Data Recording

Catalyst keg handling unit with level monitoring

Vacuum level monitoring - 2 inputs

Thermocouple input module - 6 inputs

Fixed 50 litre stainless steel catalyst tank with level monitoring

IMPS input module - 4 Inputs

How to specify / order

| Machine Item/Option | Notes | Part/Option Number |

|---|---|---|

| Ciject Five Injection Machine | Gear pump based infusion machine | XE-5000 |

| Polyester Version | 0.75% - 2.25% ratio range (typical for 2 - 20 L/min output) | 01 |

| Epoxy Version 2:1 | 100:20 - 100:40 ratio range (others available) | 02 |

| Options | ||

| Onboard Vacuum Pump | 03 |

|

| Catalyst Keg Handling Unit | With level monitoring | 06 |

| Vacuum Level Monitoring | x 2 included | 07 |

| Thermocouple Module | x 6 inputs included | 08 |

| Fixed Catalyst Tank | 50 L stainless tank with level monitoring | 09 |

| Data Recording | 10 |

|

| Spares Kits | XE-5000-SK |

|

| Polyester Option | 01 | |

| Epoxy Option | 02 | |

| Servicing | ||

| Ciject Five Service | XE-5000-SERVICE |

To specify a machine configuration use the machine part number followed by the required option numbers separated by a hyphen.

e.g. XE-5000-01-03 specifies a Polyester Version with On Board Vacuum Pump