CI Library

Composite Education at Your Finger Tips

Browse by Resource Type:

Datasheet – Mould Seals

A comprehensive range of mould seals and “formers” used in the tool making process.;

Mould Tooling For Fibre-Reinforced Polymer Composites

CI proudly contributed to this ‘Good Practice Guide’ With UK Composites & the NCC. A must-read when aiming for precision and sustainability in composite manufacturing.

This is How You Achieve Quality at Rate

In the race to fulfil demand, aerospace manufacturers are turning away from slow, wasteful and capital intensive pre-preg processes. Read why RTM and Direction Infusion are at the forefront in addressing these challenges.

Composite Integration Brochure 2024

Discover how CI’s tailored industry solutions can optimise your composites manufacturing processes. Explore our brochure to learn about our core equipment, key services, and real-world applications.

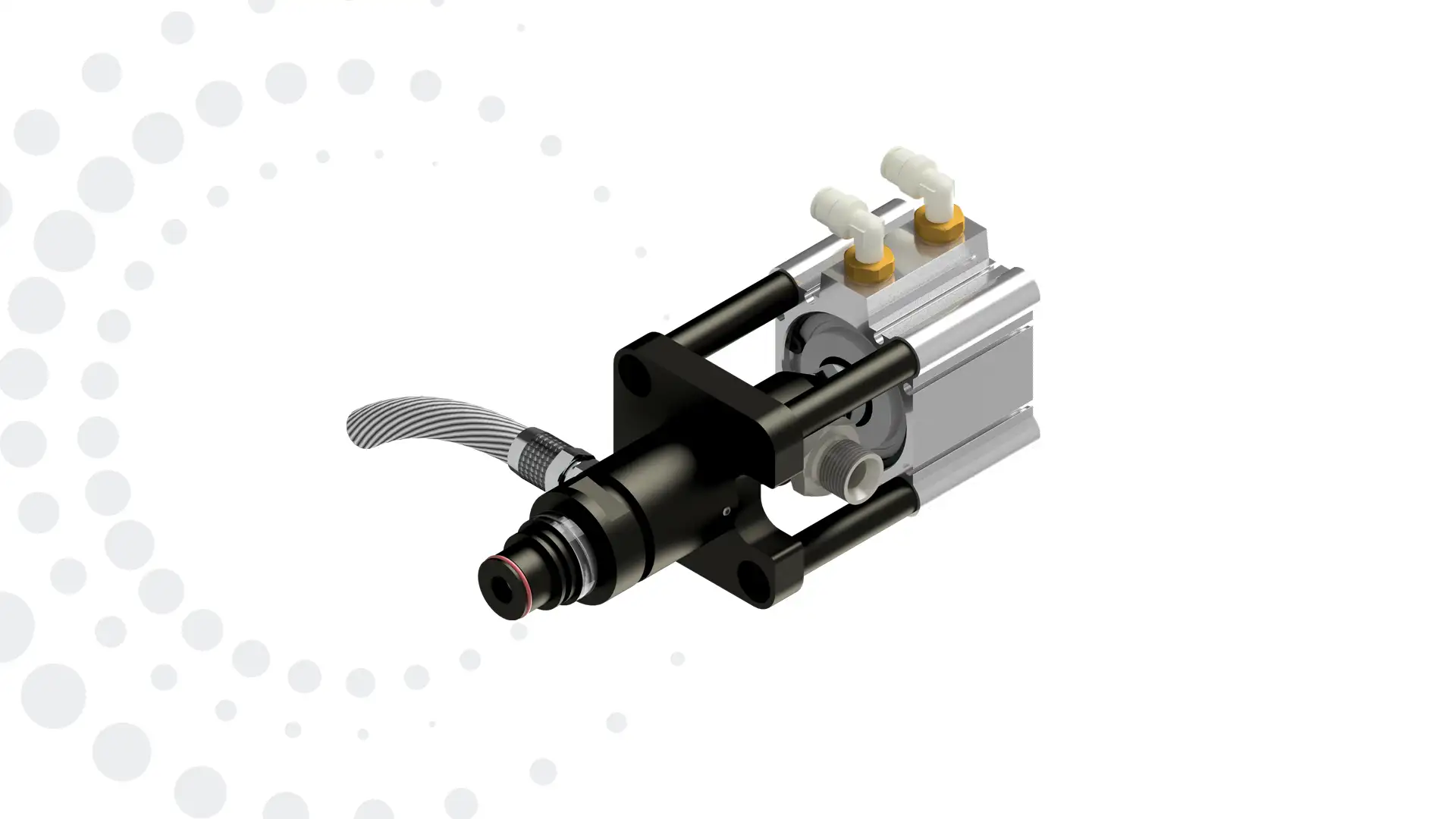

Datasheet: Injection Valve

CI injection valves ensure vacuum-tight seals and easy isolation for closed moulds, with automated functionality for reduced operator effort. Robust design enhanches reliability and performance.

Datasheet: CIVAC 3

Dry-running vacuum system, suited for medium to large RTM & Direct Infusion.

Datasheet: CIVAC 2

Oil filled system suited to small/medium Direct Infusion applications.

Datasheet: CIJECT SC4

3 component machine, to spray/dispense silicone with a 1:1 mix ratio and thixotropic additive.

Datasheet: CIJECT SC2

Dispense/spray silicones at 1:1 mix ratio. 2×25 litre material tanks.

Datasheet: CIJECT SC1

Portable machine, to dispense/spray silicones at a 1:1 mix ratio. 2×2.5 litre material tanks.

Datasheet: CIJECT 8

High performance 3 component resin mixing and injection machine. Multi programmable recipes, component flow meters and IMPS.