Wind Blade Turbine Manufacturer

One machine produces multiple parts for wind blade turbine manufacturer

Background

Headquartered in Denmark, with production centres around the world, our client manufactures composite nacelle and spinners, supplying over 70,000 wind blade turbines globally.

Challenge

Our client had ambitious efficiency targets for their production line, but their existing machines and processes weren’t capable of delivering the functionality needed to hit their KPIs.

Our client asked CI:

- Can we have one machine which delivers multiple different components requiring different recipes and setups?

- Can we have a system which automatically identifies parts and programmes for each mould tool?

- Can we automate the recording of production data for each part?

- Can we make the housekeeping of equipment more efficient?

Solution

Working closely with our client, our CI experts:

- Assessed our client’s current production setup.

- Scoped an automated process to deliver multiple different components using different recipes and setups.

- Integrated an RFID scanner to identify parts and select the appropriate recipe for each mould tool.

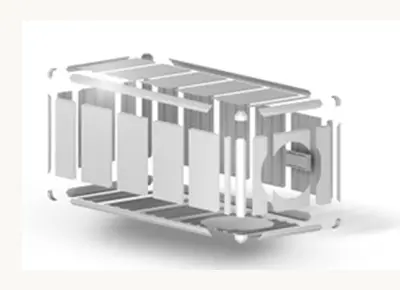

- Specified a CIJECT 2 machine with an optimised flush cycle.

- Configured CIJECT software to deliver production data including volumes for each tool line.

- Installed and calibrated the production solution onsite.

- Trained our clients staff, equipping them with the skills, knowledge, and confidence to continue the process independently.

Results

Our clients have:

- Automated the production of multiple different components requiring different recipes and setups through a single CIJECT 2 machine.

- Reduced setup times using RFID to automatically identify parts and programmes for each mould tool.

- Increased housekeeping efficiency, utilising the optimised flush cycle on their CIJECT 2 machine.

- Reduced admin overheads by automating the collection of production volumes data.