Damen Shipyards Group

Award winning eco waterbus built with our expertise and CIJECT machines

Background

The Damen Group is a Dutch defence, shipbuilding, and engineering conglomerate company based in Gorinchem, Netherlands. Though it is a major international group trading in 120 countries, with a €3.1 billion turnover and 35 shipyards worldwide, it remains a private family-owned company.

Damen are committed to securing tomorrow for the next generation, caring for our oceans, seas, lakes and rivers. They aim to combine their 97 year heritage with innovation to become the world’s most sustainable shipbuilder.

Challenge

Damen were first introduced to our expert team at a training event run by our partners, Metyx. At the time, Damen were infusing by hand, with buckets.

Having completed a costing exercise on a catamaran build, they calculated that the CAPEX for our Direct Infusion kit would pay for itself within two builds. We completed the Direct Injection test build for them within a week.

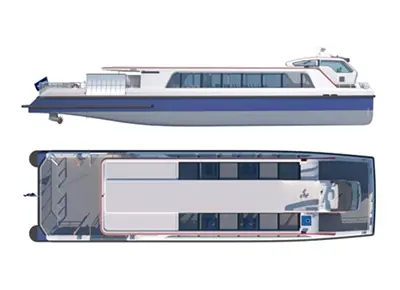

Damen returned to us with another pioneering project challenge: how to build the hull and deck of a 29m lightweight carbon composite, electric powered catamaran waterbus.

Damen asked CI:

- Can we produce lightweight carbon fibre epoxy hull and deck parts using Direct Infusion?

- Can we produce the parts for the pioneering waterbus design, aimed at enhancing the passenger experience?

- Can we maintain quality, integrity and safety standards in line with the brand’s reputation and industry expectations?

- Can we implement the infusion process successfully on the first attempt? (Carbon epoxy materials are hugely expensive)

Solution

Working closely with the Damen team, our CI experts:

- Reviewed Damen’s existing infusion strategy.

- Reviewed the deck and hull part designs.

- Scoped an automated Infusion and RTM process, optimised to deliver the epoxy carbon materials mix to the specifications of the part designs.

- Specified a versatile CIJECT 2 machine with an optimised flush cycle to reduce waste.

- Specified data collection instrumentation.

- Installed and calibrated the test-bed solution onsite.

- Helped infuse the first 30m x 10m deck part.

- Analysed the data to further de-risk production.

- Provided a production options strategy for the Damen team.

- Trained Damen’s staff, equipping them with the skills, knowledge, and confidence to continue the process independently.

Results

- Test production was successful on the first attempt.

- Damen moved to full production using CIJECT machinery.

- The Waterbus 2907 E3 won a G100 Dutch Design award for innovation and exceptional design in October 2023.