RTM & VRTM

Resin Transfer Composite Technologies

Pioneering Advanced Manufacturing Solutions

At Composite Integration, we take pride in being at the forefront of composite technology, specialising in Resin Transfer Moulding (RTM) and Vacuum Resin Transfer Moulding (VRTM). Our innovative approach to Direct Infusion processes sets industry standards, leading to more efficient, cost-effective, and robust composite manufacturing.

Resin Transfer Moulding (RTM) is an advanced composite manufacturing technique used to produce high-quality, dimensionally accurate components. This process involves injecting liquid resin into a closed mould containing fibre reinforcement, ensuring thorough fibre impregnation under pressure.

What is Resin Transfer Moulding (RTM)?

Resin Transfer Moulding (RTM) is an advanced composite manufacturing technique used to produce high-quality, dimensionally accurate components. This involves injecting liquid resin into a closed mould where the fibre reinforcement material has been placed, ensuring thorough impregnation of fibres under pressure.

Key Features of RTM:

Precision

Excellent control over resin content & fibre placement, for consistent parts & minimal void content.

Quality Finish

Achieves a smooth finish on both sides of the part, reducing post-processing work.

Versatility

Adapts to various materials e.g. glass, carbon & aramid fibres, suitable for producing complex shapes.

Scalability

Suitable for both small batch production and large-scale manufacturing projects.

RTM is invaluable in sectors such as aerospace, wind, marine, automotive, and defence, where component integrity is critical. It allows precise control over resin and fibre ratios, optimising the performance characteristics of the final product.

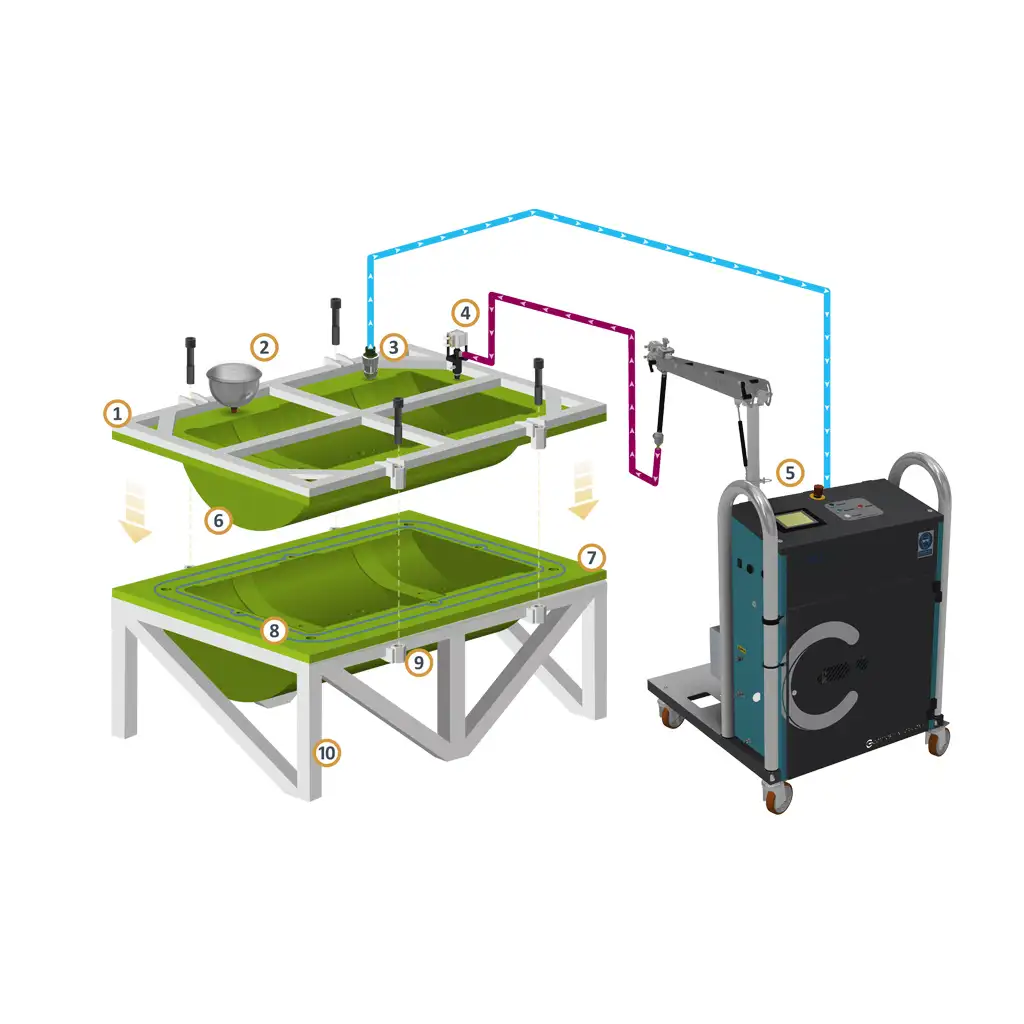

Typical RTM Set-Up

- Support frame – lightweight metal

- Catch-pot – waste removal

- Sensor monitoring – data measurement

- Injection valve – resin input

- CIJECT 2 – resin mixing & injection

- Mould – ‘B’ surface

- Mould ‘A’ surface

- Seals – standard groove fitting

- Clamping point – manual nut/bolt

- Support frame – steel reinforcement

What is Vacuum Resin Transfer Moulding (VRTM)?

Vacuum Resin Transfer Moulding (VRTM) is an advanced form of resin infusion for producing large and structurally complex composite components. This technique involves laying dry fibre reinforcements within a mould, covered by a vacuum bag to compact the fibres as resin is introduced under atmospheric pressure, drawing the resin through the mould.

Key Features of VRTM

Large Scale Production

Ideal for creating large structures such as wind turbine blades, boat hulls, and automotive panels.

High Quality and Uniformity

The use of a vacuum ensures consistent resin flow, reducing voids and ensuring uniform properties.

Cost Efficiency

More economical for large parts due to cheaper materials and reduced labour costs.

Flexibility

Accommodates various reinforcement materials and resin types, tailored to specific needs.

VRTM’s capability to maintain quality at scale makes it preferred for industries needing large, strong, and lightweight composite parts.

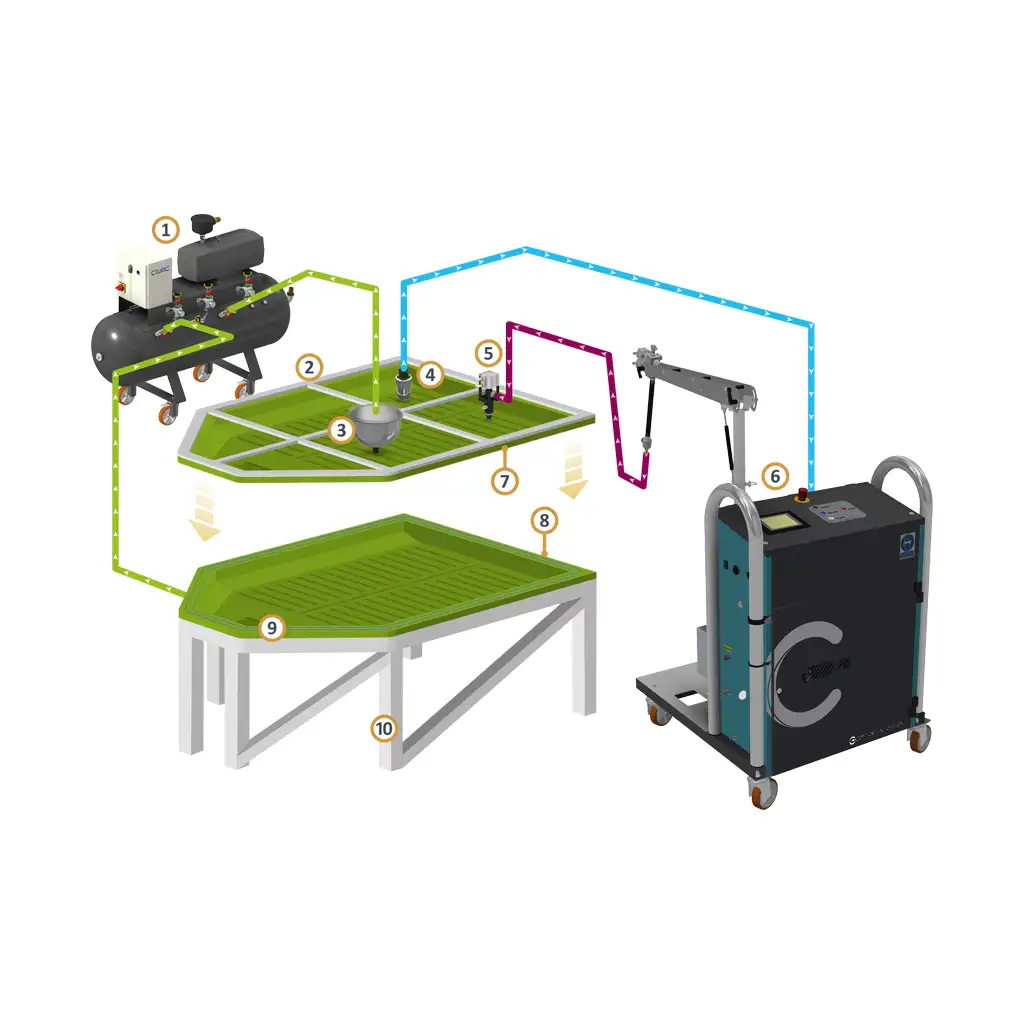

Typical VRTM Set-Up

- Support frame – lightweight metal

- Catch-pot – waste removal

- Sensor monitoring – data measurement

- Injection valve – resin input

- CIJECT 2 – resin mixing & injection

- Mould – ‘B’ surface

- Mould ‘A’ surface

- Seals – standard groove fitting

- Clamping point – manual nut/bolt

- Support frame – steel reinforcement

Why Choose Composite Integration?

Our cutting-edge solutions are brought to life through our range of CIJECT machinery. Engineered with your needs in mind, CIJECT delivers unmatched precision and quality.

Customisation

We engineer components to meet unique requirements, enhancing performance and efficiency.

Cost-Effective Production

Our processes reduce costs through efficient resin usage and minimal waste.

Industry-Leading Expertise

Our extensive experience in composite manufacturing gives you a competitive edge.

Global Reach

We design, manufacture, and test our equipment, with a network of distributors in over twenty countries worldwide.

At Composite Integration, we are committed to pushing the boundaries of composite manufacturing. Our advanced RTM and VRTM capabilities, combined with our pioneering work in Direct Infusion, enable us to tackle the most challenging projects and deliver exceptional results.

Explore Our Case Studies

Get in Touch

Contact us today to find out how our state-of-the-art composite manufacturing solutions can elevate your products. Join us in setting new standards in the industry.

Chat to the CI team today.