RESIN INFUSION

& DIRECT INFUSION

The Future for Advanced Composite Manufacturing

Elevating Industry Standards with Composite Integration

At Composite Integration, we are dedicated to advancing composite manufacturing technologies through our expertise in Resin Infusion (RI) and our pioneering development of Direct Infusion processes.

These innovative methods have set new industry standards, particularly for the efficient production of large-scale structures, with exceptional quality outcomes.

What is Resin Infusion?

Resin Infusion (RI) is a process where resin is drawn into a dry laminate under vacuum. This method uses a rigid mould covered by a flexible membrane, typically a disposable film vacuum bag, sealed against the mould’s edges with sealant tape. This technique is highly relevant for creating very large structures due to its relatively low tooling costs. While the cosmetic finish of the ‘B’ surface in resin infusion isn’t as tightly controlled as in other methods, such as RTM, the laminate properties achieved are exceptional. Additionally, Resin Infusion significantly reduces volatile emissions compared to large-scale open moulding, making it an environmentally preferable option in composite manufacturing.

Recent advancements, such as the introduction of renewable silicone vacuum membranes, have broadened the application scope of Resin Infusion, potentially reducing the costs associated with consumable materials.

Direct Infusion Brought to You by Composite Integration

Building on the principles of traditional resin infusion, Composite Integration has pioneered the Direct Infusion process, specifically designed to address the scalability challenges of large structures.

Recognising the limitations of hand-mixing resin, which becomes impractical and inconsistent at large scales, we developed a mechanised approach using meter-mix machines. These machines dispense mixed resin directly on demand, reducing material wastage and ensuring consistent ratios.

Our Direct Infusion technology goes even further by integrating in-mould pressure sensors (IMPS) within the infusion setup. These sensors enable monitoring infusion pressure, controlling flow rate, and regulating volumetric compression, facilitating a completely automated and precise control over the infusion process.

This level of automation and control is critical when working with large-scale infusions, enhancing the efficiency, consistency, and quality of the final product.

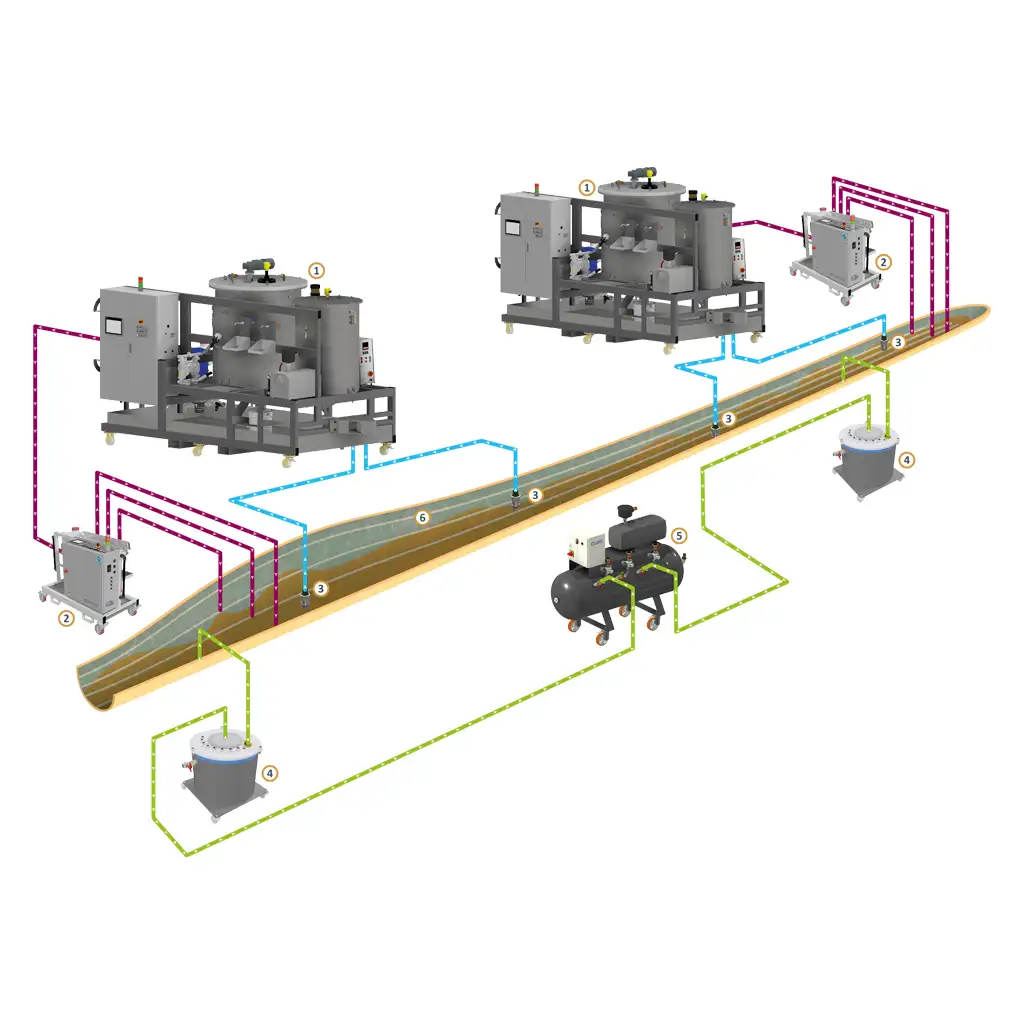

Typical Direct Infusion for Large Wind Structure

1. CIJECT 5 – resin mixing & infusion

2. Manifold – resin distribution

3. IMPS – data feedback & control

4. Catch-Pot – contaminant protection

5. CIVAC pump – vacuum system

6. Consumables -infusion film & PVC

Why Choose Composite Integration for Resin Infusion & Direct Infusion?

Innovative Solutions

Leverage our cutting-edge Direct Infusion technology for unmatched precision and quality.

Cost Efficiency

Our advanced CIJECT equipment reduces the need for extensive manual labour and material waste.

Enhanced Quality

Achieve superior laminate properties with our controlled infusion processes.

Environmental Responsibility

Benefit from our methods that significantly cut down on volatile emissions.

Composite Integration is at the forefront of transforming resin infusion into a more efficient and scalable process with our proprietary Direct Infusion technology. This innovation exemplifies our commitment to pushing the boundaries of what is possible in composite manufacturing.

Ready To Enhance Your

Manufacturing Processes?

Contact us today to learn how our state-of-the-art Resin and Direct Infusion technologies can enhance your manufacturing processes. Whether you are creating vast industrial components or detailed architectural elements, our solutions are designed to deliver superior results that meet rigorous industry standards.

Join us in redefining composite manufacturing for the future.