www.composite-integration.co.uk

info@composite-integration.co.uk

Tel +44 (0)1752 849998

Fax +44 (0)1752 846414

Composite Integration Ltd

1F Long Acre, Saltash, PL12 6LZ

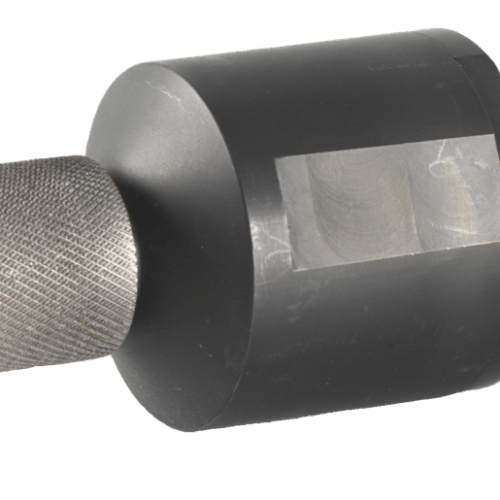

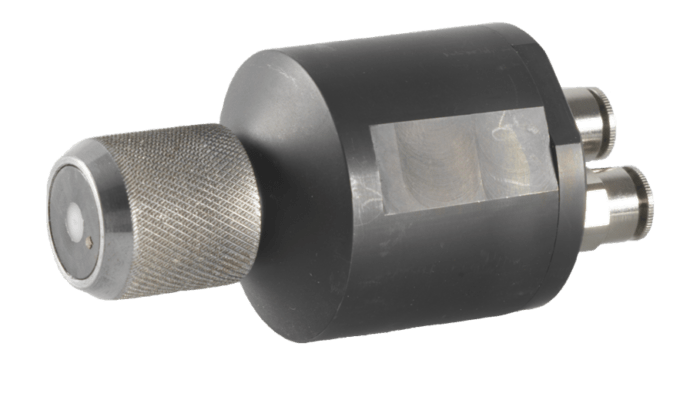

In-Mould Air Ejector

A valve which provides an efficient method of removing cured mouldings without the mould damage associated with wedges or mechanical force.

The in-mould air ejector is designed to be fitted into a composite or a metal mould, with specific mould inserts which can be provided for fitting into either composite or metal tooling.

Features include:

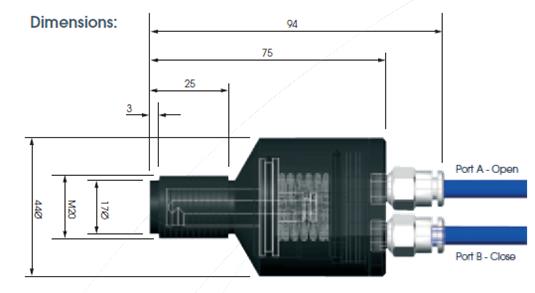

- Designed to provide maximum air-flow with the minimum of interference with the mould surface

- The 17 mm flush end surface is considerably smaller than most other units currently available

- The high opening force created by the larger integral piston at the rear of the valve ensures reliable and powerful operation

- Machined from steel and treated to provide a hardened and corrosion resistant surface

- The standard version has a maximum operating temperature of 80°C

- A high temperature version has a working temperature limit of 180°C and a maximum temperature limit of 200°C

- Standard metric thread to enable threading into the mould structure and easy removal

- Closing force is provided by an internal spring but air pressure can be applied if working against high in-mould pressures

- Air connections positioned in the end-cap surface to enable easy access once installed

- Remote operation by pneumatic push-button switch connected via 6 mm pipes and fittings

- Single push-button may be used to operate multiple ejectors

How to Specify/Order

| Valve Item/Option | Notes | Part/Option Number |

|---|---|---|

| Air Ejector | Standard version Includes mould insert for composite tooling | XE-0020 |

| Options | ||

| Standard Version | Without mould insert for composite tooling | 01 |

| High Temperature Version | For use up to 150°C | 02 |

| Associated Parts | ||

| 5/2 Pneumatic Push Button Control Valve | Includes pipes and connectors | XE-0021 |

| Air Ejector Mould Insert | For use in composite tooling | XA-2001 |

| Air Ejector Mould Insert | For use in metal tooling | XA-2006 |

| Air Ejector Blanking Plug | XA-2007 |

Note: All specifications are subject to change without notice.