www.composite-integration.co.uk

info@composite-integration.co.uk

Tel +44 (0)1752 849998

Fax +44 (0)1752 846414

Composite Integration Ltd

1F Long Acre, Saltash, PL12 6LZ

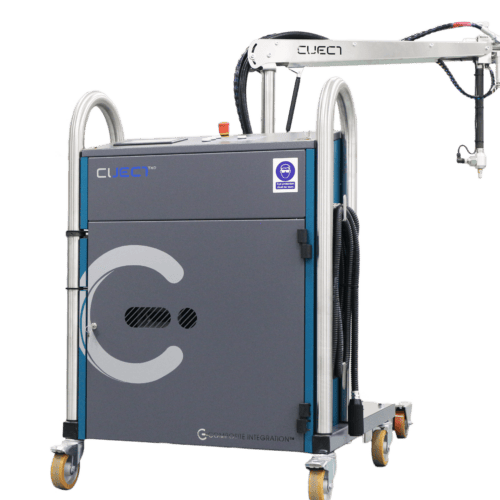

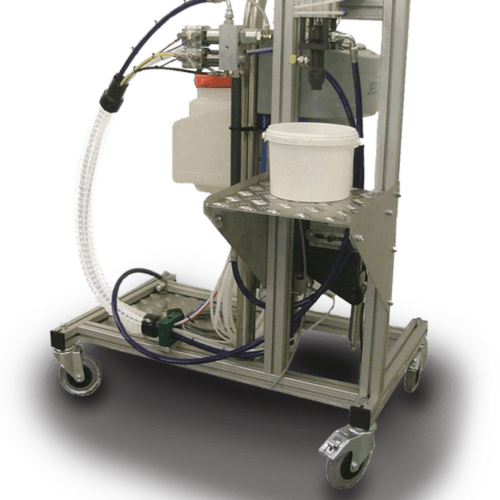

Ciject Three- Equipment for advanced composites.

The Ciject Three range is the result of several years of focused development work in advanced composite manufacturing technology.

Working with tier-one aerospace and advanced materials manufacturers in combination with collaborative project work, such as the AMSCI funded Propound project, has enabled us to develop the most advanced equipment currently available.

A combination of advanced control methodology and intelligent process mapping enables a step towards the target of ‘Industry 4.0’.

Originally developed for R&D and lab-scale processing, the Ciject Three had now been developed further to suit the specific requirements of the aerospace and other hi-tech composite manufacturing industries. These machines allow different resin systems to be prepared (i.e. heated, mixed, degassed) and then dispensed without the need to clean and re-prime a mechanical pumping system.

The accurate output control allows the machine to be used in both RTM and RI processes.

Three versions are available:

• Ciject 3.0 – A basic version of the machine with a relatively simple manual control system, aimed at processing room-temperature curing resin systems or resins that require limited heating.

• Ciject 3.1 – An evolution of the Ciject 3.0, with touch screen control and capacity for processing higher temperature resin systems.

• Ciject 3.2 – The most sophisticated version controlled via a powerful PLC with a touch-screen HMI.

This enables the addition of more complex control and monitoring options.

| Ciject 3.0 XE-3000-000 | Ciject 3.1 XE-3000-001 | Ciject 3.2 XE-3000-002 | ||||

|---|---|---|---|---|---|---|

| Item | Notes | Notes | Notes | |||

| Capacity | Total volume of vessel 7.5 litres maximum resin capacity 2.5 litres | Total volume of vessel 27 litres maximum resin capacity 10 litres | Total volume of vessel 27 litres maximum resin capacity 10 litres | |||

| Container Size | To accept plastic or metal resin container with maximum diameter of 220mm and maximum height of 180mm | To accept 5 or 10 litre metal resin containers Nominal maximum container dimensions: 5 Litre; 180Ø x 230H 10 Litre; 230Ø x 260H 10 Litre; 230Ø x 330H | To accept 5 or 10 litre metal resin containers Nominal maximum container dimensions: 5 Litre; 180Ø x 230H 10 Litre; 230Ø x 260H 10 Litre; 230Ø x 330H | |||

| Vessel/Lid Lifting | Manually removable lid | Manually operated screw jack system to lift vessel | Pneumatically actuated and damped vessel lifting system | |||

| Lid Locking | 4 x manually tightened swing-bolts | Manually Tightened - Captive Bolts | Manually Tightened- Captive Bolts (See option 19 for automated version) | |||

| Vessel Base | Vessel incorporates an angled base to allow maximum amount of resin to be used | Vessel incorporates an angled base to allow maximum amount of resin to be used | Vessel incorporates an angled base to allow maximum amount of resin to be used | |||

| Resin Outlet | Through-lid fitting to take 10mm OD pipe | 1x ¾” BSPP port in lid 1x ¾” BSPP port in vessel wall | 1x ¾” BSPP port in lid 1x ¾” BSPP port in vessel wall | |||

| Pressure | Working pressure 1 mbar to 7 bar (ABS) | Working pressure 1 mbar to 7 bar (ABS) | Working pressure 1 mbar to 7 bar (ABS) | |||

| Over-Pressure Safety | Mechanical over-pressure valve | Mechanical over-pressure valve | Mechanical over-pressure valve with integrated exotherm management system | |||

| Compressed Air Requirement | Requires external compressed air supply (7 bar minimum) | Requires external compressed air supply (7 bar minimum) | Requires external compressed air supply (7 bar minimum) | |||

| Vacuum Requirement | Requires external vacuum supply | Requires external vacuum supply (See option for integrated on-board vacuum pump) | Requires external vacuum supply (See option for integrated on-board vacuum pump) | |||

| Viewing port | N/A | Through-lid viewing port | Through-lid viewing port (see option for through-lid camera) | |||

| Vessel Pressure Monitoring | Analogue gauge | 0-10bar (ABS) pressure transducer | 0-10bar (ABS) pressure transducer | |||

| Mould Outlet Connection | 10mm disposable tube | 10mm disposable tube with manually operated pinch valve to start/stop process | 12mm disposable tube with pneumatically actuated pinch valve to start/stop process controlled from HMI. | |||

| PLC | N/A | Omron PLC | Modular Siemens PLC | |||

| Screen/HMI | If Options 01,03 or 04 are selected, heater control/ display through discrete controllers | 3.5” Omron HMI | 12” touch screen Siemens TFT HMI | |||

| Pressure Control | Manual Regulators for vacuum and positive pressure | Electronic pressure control (pressure and vacuum) Controlled from and displayed on HMI | Electronic pressure control (pressure and vacuum) Controlled from and displayed on HMI See option: Closed-loop PID feed-back control of positive and negative pressure from internal or external sensor (e.g. IMPS) | |||

| Power Supply | 13A 240V | 16A 240V | 32A 415V | |||

| Framework | Fabricated steel chassis supporting vessel and control cabinet | Fabricated steel chassis supporting vessel and control cabinet | Fabricated steel chassis supporting vessel and control cabinet | |||

| Mobility | Machine mounted on wheels (2 x locking) | Machine mounted on wheels (2 x locking) | Machine mounted on wheels (2 x locking) | |||

| Outlet hose support boom | Adjustable boom to support outlet hose | Adjustable boom to support outlet hose | Adjustable boom to support outlet hose |

| Ciject 3.0 XE-3000-000 | Ciject 3.1 XE-3000-001 | Ciject 3.2 XE-3000-002 | ||||

|---|---|---|---|---|---|---|

| Item | Notes | Notes | Notes | |||

| Capacity | Total volume of vessel 7.5 litres maximum resin capacity 2.5 litres | Total volume of vessel 27 litres maximum resin capacity 10 litres | Total volume of vessel 27 litres maximum resin capacity 10 litres | |||

| Container Size | To accept plastic or metal resin container with maximum diameter of 220mm and maximum height of 180mm | To accept 5 or 10 litre metal resin containers Nominal maximum container dimensions: 5 Litre; 180Ø x 230H 10 Litre; 230Ø x 260H 10 Litre; 230Ø x 330H | To accept 5 or 10 litre metal resin containers Nominal maximum container dimensions: 5 Litre; 180Ø x 230H 10 Litre; 230Ø x 260H 10 Litre; 230Ø x 330H | |||

| Vessel/Lid Lifting | Manually removable lid | Manually operated screw jack system to lift vessel | Pneumatically actuated and damped vessel lifting system | |||

| Lid Locking | 4 x manually tightened swing-bolts | Manually Tightened - Captive Bolts | Manually Tightened- Captive Bolts (See option 19 for automated version) | |||

| Vessel Base | Vessel incorporates an angled base to allow maximum amount of resin to be used | Vessel incorporates an angled base to allow maximum amount of resin to be used | Vessel incorporates an angled base to allow maximum amount of resin to be used | |||

| Resin Outlet | Through-lid fitting to take 10mm OD pipe | 1x ¾” BSPP port in lid 1x ¾” BSPP port in vessel wall | 1x ¾” BSPP port in lid 1x ¾” BSPP port in vessel wall | |||

| Pressure | Working pressure 1 mbar to 7 bar (ABS) | Working pressure 1 mbar to 7 bar (ABS) | Working pressure 1 mbar to 7 bar (ABS) | |||

| Over-Pressure Safety | Mechanical over-pressure valve | Mechanical over-pressure valve | Mechanical over-pressure valve with integrated exotherm management system | |||

| Compressed Air Requirement | Requires external compressed air supply (7 bar minimum) | Requires external compressed air supply (7 bar minimum) | Requires external compressed air supply (7 bar minimum) | |||

| Vacuum Requirement | Requires external vacuum supply | Requires external vacuum supply (See option for integrated on-board vacuum pump) | Requires external vacuum supply (See option for integrated on-board vacuum pump) | |||

| Viewing port | N/A | Through-lid viewing port | Through-lid viewing port (see option for through-lid camera) | |||

| Vessel Pressure Monitoring | Analogue gauge | 0-10bar (ABS) pressure transducer | 0-10bar (ABS) pressure transducer | |||

| Mould Outlet Connection | 10mm disposable tube | 10mm disposable tube with manually operated pinch valve to start/stop process | 12mm disposable tube with pneumatically actuated pinch valve to start/stop process controlled from HMI. | |||

| PLC | N/A | Omron PLC | Modular Siemens PLC | |||

| Screen/HMI | If Options 01,03 or 04 are selected, heater control/ display through discrete controllers | 3.5” Omron HMI | 12” touch screen Siemens TFT HMI | |||

| Pressure Control | Manual Regulators for vacuum and positive pressure | Electronic pressure control (pressure and vacuum) Controlled from and displayed on HMI | Electronic pressure control (pressure and vacuum) Controlled from and displayed on HMI See option: Closed-loop PID feed-back control of positive and negative pressure from internal or external sensor (e.g. IMPS) | |||

| Power Supply | 13A 240V | 16A 240V | 32A 415V | |||

| Framework | Fabricated steel chassis supporting vessel and control cabinet | Fabricated steel chassis supporting vessel and control cabinet | Fabricated steel chassis supporting vessel and control cabinet | |||

| Mobility | Machine mounted on wheels (2 x locking) | Machine mounted on wheels (2 x locking) | Machine mounted on wheels (2 x locking) | |||

| Outlet hose support boom | Adjustable boom to support outlet hose | Adjustable boom to support outlet hose | Adjustable boom to support outlet hose |

| Ciject 3.0 XE-3000-000 | Ciject 3.1 XE-3000-001 | Ciject 3.2 XE-3000-002 | ||||

|---|---|---|---|---|---|---|

| Item | Notes | Part No | Notes | Part No | Notes | Part No |

| Vessel Base Heater – Heating elements mounted in base of pressure vessel | Electrical vessel heating designed to maintain resin temperature up to 50°C Discrete PID control | OPT-01 | Electrical heating (in contact with base of resin container) of maximum 120°C All heated elements are protected by external insulation Discrete PID control | OPT-01 | Electrical heating (in contact with base of resin container) of maximum 120°C All heated elements are protected by external insulation Multi-channel PID controlled from and displayed on HMI | OPT-01 |

| Vessel Band Heater – Silicone band heater, mounted to outside of tank | N/A | Silicone band heater with control thermocouple Maximum temperature 120°C All heated elements are protected by external insulation Discrete PID control | OPT-02 | Silicone band heater with control thermocouple Maximum temperature 120°C All heated elements are protected by external insulation Multi-channel PID controlled from and displayed on HMI | OPT-02 | |

| 2m Heated Hose Sleeve | Electrical heating of pipework and associated fittings Maximum temperature 120°C Discrete PID control | OPT- 03 | Electrical heating of pipework and associated fittings Maximum temperature 120°C Full PID controlled from the HMI | OPT-03 | Electrical heated sleeve with insulation Fits over the output silicone hose to keep resin at temperature between the machine and mould Maximum temperature 120°C Full PID controlled from the HMI | OPT-03 |

| 3m Heated Hose Sleeve | Electrical heating of pipework and associated fittings Maximum temperature 120°C Discrete PID control | OPT-04 | Electrical heating of pipework and associated fittings Maximum temperature 120°C Full PID controlled from the HMI | OPT-04 | Electrical heated sleeve with insulation Fits over the output silicone hose to keep resin at temperature between the machine and mould Maximum temperature 120°C Full PID controlled from the HMI | OPT-04 |

| Resin Temperature Probe – Lid mounted | N/A | 0–200°C single point temperature probe | OPT-05 | 0–200°C single point temperature probe | OPT-05 | |

| Infrared Thermocouple – Lid mounted | N/A | N/A | Contactless resin temperature monitoring 0–200°C | OPT-06 | ||

| Resin Weight Monitoring | Digital weighing scales with integral display 0–10kg measuring range (±0.001kg resolution) | OPT-07 | Integrated load weighing platform Readout on HMI 0–10kg measuring range (±0.001kg resolution) | OPT-08 | Integrated load weighing platform Readout on HMI 0-10kg measuring range (±0.001kg resolution) | OPT-08 |

| Vacuum Pump | N/A | 6m³/hr vacuum pump 1mbar (ABS) for degassing | OPT-09 | 6m³/hr vacuum pump 1mbar (ABS) for degassing | OPT-09 | |

| Vacuum Pump | N/A | 16m³/hr vacuum pump 1 mbar (ABS) for degassing and external connection (i.e. mould vacuum) | OPT-10 | 16m³/hr vacuum pump 1 mbar (ABS) for degassing and external connection (i.e. mould vacuum) | OPT-10 | |

| Vacuum Fittings | N/A | Additional pipework/fittings for external vacuum connection This is required if you want to use the on-board vacuum pump (Options 09 or 10) to evacuate mould | OPT-11 | Additional pipework/fittings for external vacuum connection This is required if you want to use the on-board vacuum pump (Options 09 or 10) to evacuate mould | OPT-11 | |

| Pneumatic Agitator | Pneumatically driven agitator with regulator to control speed | OPT-12 | Pneumatically driven agitator with regulator to control speed | OPT-12 | N/A | |

| Electrical Agitator | N/A | N/A | Electrically driven variable speed stirrer/agitator Speed control from HMI (0–60 rpm) | OPT-13 | ||

| Control from External Sensors (IMPS) | N/A | N/A | Closed loop PID pressure control – Automatic, regulated tank pressure to achieve the desired pressure in the mould Additional sensor inputs (OPT-17) must be chosen with this option for the sensors to connect to the machine Includes 4 x high temperature IMPS sensors (maximum temperature 120°C) and 4 x 10m extension leads | OPT-15 | ||

| Temperature | N/A | N/A | Inputs for 4 remote K type thermocouples | OPT-16 | ||

| Additional Sensor Inputs | N/A | N/A | 4 x 0–10 V analogue inputs Displayed on HMI | OPT-17 | ||

| Mechanised Lid Locking | N/A | N/A | Quick access rotating castellated vessel/lid locking mechanism | OPT-18 | ||

| Secomea Remote Support | N/A | N/A | SECOMEA communication system -Permits remote support and upgrades by Composite Integration Operates on Ethernet or Wi-Fi network with full security certification | OPT-19 | ||

| Through-lid Viewing Camera | N/A | N/A | Illuminated viewing camera mounted through vessel lid to visually monitor the interior of vessel Output displayed on HMI | OPT-20 | ||

| Data Log to USB | N/A | All machine and process parameters time stamped and logged to a SD/USB drive in CSV format (including pressure, temperature, resin weight, external sensors) | OPT-21 | All machine and process parameters time stamped and logged to a SD/USB drive in CSV format (including pressure, temperature, resin weight, external sensors) | OPT-21 |

To specify a machine configuration use the machine part number followed by the required option numbers separated by a hyphen.

e.g. XE-3000-001-03-09-12 specifies a Ciject 3.1 machine with a 2m heated output hose, integral 6m³/hr vacuum pump and pneumatically driven agitator

Please contact Composite Integration for more details or to the discuss the most suitable specification for your application.