ABOUT CIJECT 1

CIJECT 1 is a two-component workshop machine that provides extensive levels of control yet retains very simple operation. With programmable injection recipes and an alarm monitored gel timer, it minimises the need for operator input throughout the process.

- Share Options

Key Features & Benefits

- PID controlled injection pressure – ensures continuous, uniform positive injection pressure.

- Pre-injection vacuum test – ensures vacuum integrity prior to injection.

- Fixed solvent & catalyst tanks with storage area for hardener and drum trolley for resin – a practical self-contained “injection unit”.

Applications

- RTM of manhole covers

- VRTM of modular building components

- VRTM with silicone bags of van roofs.

- Small infusions

Datasheet

Where To Buy

Looking to purchase this product? Visit our Worldwide Partners page to find a distributor near you. Our global network of trusted partners is ready to assist with your Composite Integration machinery needs. Click the button below to view the map and get in touch with your local distributor.

You May Also Need

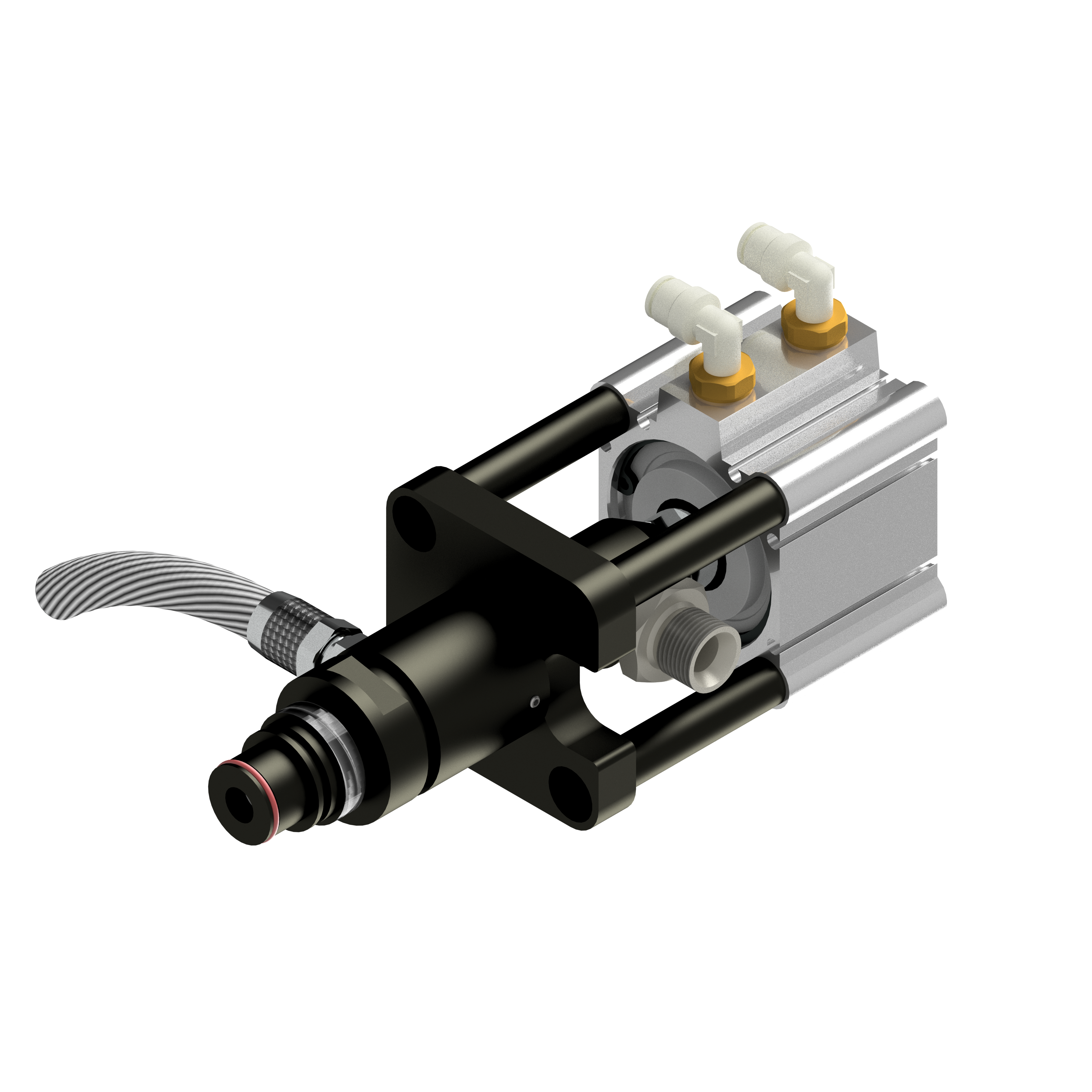

Injection Valve

Part Number:

XE-0015

Vacuum Catch-Pot – c/w Lid

Part Number:

XE-0211

Inline Resin Trap

Part Number:

XE-0213